Shielded Metal Arc Welding, 10th Edition

Special Price $98.05 Regular Price $108.95

In stock

Product Code

9781637760697

Shielded Metal Arc Welding provides thorough instruction in the shielded metal arc welding process through 35 concise and easy-to-understand lessons. Each new concept is presented in a separate unit, allowing students to focus on one area of instruction at a time. Students will find the concise, write-in text unintimidating and clearly illustrated as they progress from the study of basic welding concepts, such as welding safety and basic weld joints, to more challenging welding techniques, such as welding thin sheet metal, aluminum, and pipe. In addition to providing instruction for shielded metal arc welding in all welding positions on ferrous and nonferrous metals, this text also provides lessons on surfacing and padding, strategies for controlling distortion, weld inspection and quality control, and welding careers.

This text helps prepare students for the Knowledge Tests and Welder Performance Qualification Tests for Module 4 of AWS SENSE Level I—Entry Welder certification. It also explains the interpretation of AWS welding symbols, teaching students to properly read welding drawings and blueprints.

- The write-in format allows students to work at their own pace; perforated sheets make it easy to turn in assignments.

- The new Procedures table of contents helps students quickly locate specific procedures within the text.

- Review questions at the end of each lesson help students and instructors evaluate the student’s level of understanding before proceeding to the next area of study.

TABLE OF CONTENTS

1. Introduction to Arc Welding

2. Measurement in Welding

3. Welding Safety

4. Common Types of Welds and Joints

5. Welding Symbols

6. Arc Welding Equipment

7. Types of Arc Welding Machines

8. Electrodes

9. Selecting the Proper Electrode

10. Joint Preparation

11. Preparing to Weld

12. Running Short Beads

13. Running Continuous Beads

14. Running Multidirectional Beads

15. Padding

16. Welding Problems - How to Solve Them

17. Controlling Distortion

18. Welding Square-Groove Joints

19. Single-Pass Fillet Lap-Joint Welds

20. Single-Pass Fillet Welds

21. Multiple-Pass Fillet Welds

22. V-Groove Butt Welds

23. Corner Joint Fillet Welds

24. Welding Round Stock

25. Welding in the Horizontal Position

26. Welding in the Vertical Position

27. Welding in the Overhead Position

28. Cutting with the Arc

29. Welding Sheet Metal

30. Hardsurfacing

31. Arc Welding Aluminum

32. Welding Pipe

33. Identifying Metals

34. Inspection and Quality Control

35. Careers in Welding

Charts

2. Measurement in Welding

3. Welding Safety

4. Common Types of Welds and Joints

5. Welding Symbols

6. Arc Welding Equipment

7. Types of Arc Welding Machines

8. Electrodes

9. Selecting the Proper Electrode

10. Joint Preparation

11. Preparing to Weld

12. Running Short Beads

13. Running Continuous Beads

14. Running Multidirectional Beads

15. Padding

16. Welding Problems - How to Solve Them

17. Controlling Distortion

18. Welding Square-Groove Joints

19. Single-Pass Fillet Lap-Joint Welds

20. Single-Pass Fillet Welds

21. Multiple-Pass Fillet Welds

22. V-Groove Butt Welds

23. Corner Joint Fillet Welds

24. Welding Round Stock

25. Welding in the Horizontal Position

26. Welding in the Vertical Position

27. Welding in the Overhead Position

28. Cutting with the Arc

29. Welding Sheet Metal

30. Hardsurfacing

31. Arc Welding Aluminum

32. Welding Pipe

33. Identifying Metals

34. Inspection and Quality Control

35. Careers in Welding

Charts

| Price | $108.95 |

|---|---|

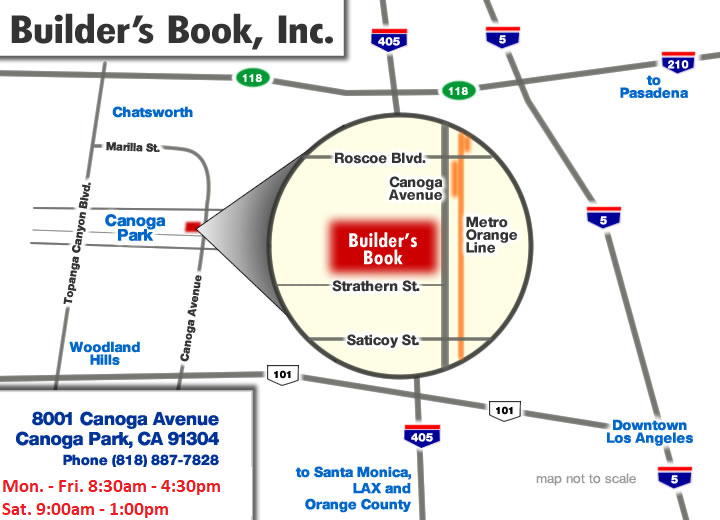

| Customer Service | We're Here To Help! Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions:

TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

|

| Description | Shielded Metal Arc Welding provides thorough instruction in the shielded metal arc welding process through 35 concise and easy-to-understand lessons. Each new concept is presented in a separate unit, allowing students to focus on one area of instruction at a time. Students will find the concise, write-in text unintimidating and clearly illustrated as they progress from the study of basic welding concepts, such as welding safety and basic weld joints, to more challenging welding techniques, such as welding thin sheet metal, aluminum, and pipe. In addition to providing instruction for shielded metal arc welding in all welding positions on ferrous and nonferrous metals, this text also provides lessons on surfacing and padding, strategies for controlling distortion, weld inspection and quality control, and welding careers.

This text helps prepare students for the Knowledge Tests and Welder Performance Qualification Tests for Module 4 of AWS SENSE Level I—Entry Welder certification. It also explains the interpretation of AWS welding symbols, teaching students to properly read welding drawings and blueprints.

TABLE OF CONTENTS 1. Introduction to Arc Welding

2. Measurement in Welding 3. Welding Safety 4. Common Types of Welds and Joints 5. Welding Symbols 6. Arc Welding Equipment 7. Types of Arc Welding Machines 8. Electrodes 9. Selecting the Proper Electrode 10. Joint Preparation 11. Preparing to Weld 12. Running Short Beads 13. Running Continuous Beads 14. Running Multidirectional Beads 15. Padding 16. Welding Problems - How to Solve Them 17. Controlling Distortion 18. Welding Square-Groove Joints 19. Single-Pass Fillet Lap-Joint Welds 20. Single-Pass Fillet Welds 21. Multiple-Pass Fillet Welds 22. V-Groove Butt Welds 23. Corner Joint Fillet Welds 24. Welding Round Stock 25. Welding in the Horizontal Position 26. Welding in the Vertical Position 27. Welding in the Overhead Position 28. Cutting with the Arc 29. Welding Sheet Metal 30. Hardsurfacing 31. Arc Welding Aluminum 32. Welding Pipe 33. Identifying Metals 34. Inspection and Quality Control 35. Careers in Welding Charts |

Check items to add to the cart or